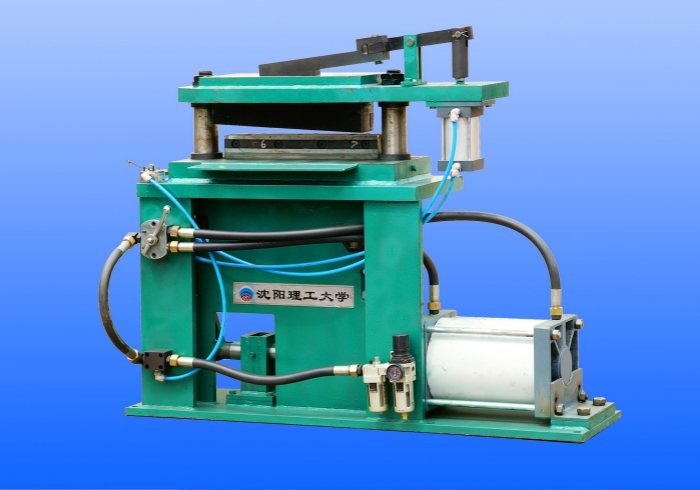

Shear End Welder

Shear end welder is becoming a essential equipment in tube mill line or other coil processing line. Shear & end welder, by eliminating rethreading, will greatly reduce scrap, tooling damage, downtime and safety hazards. Another big benefit for utilizing shear & end welder is the reduction of time spent during the coil change.

SRET Equipment designs and manufactures stationary shear end welder machine that comes in various design from semi-automatic to fully automatic. The operation starts by jogging the tail end into shearing position. Then the strip is edge guided automatically or manually for centering adjustment. The tail end is then clamped and sheared. The lead end of the new coil is fed into position, edge guided, clamped and sheared. The sheared scrap can be removed manually or automatically. After shearing process done, the weld torch is initiated, joining the two coil ends together. After the welding is done, the machine is reset for the next work cycle. At SRET Equipment’s shear end welder machine, the TIG or MIG weld process is applied, that have proven to be the best and most cost-effective welding for tube mill industry. The automatically driven weld torch allows for a smooth and consistent weld bead across the seam of material.

Value Highlights

- Reduction of coil changeover time for a significant increase in work efficiency

- Great reduction in tooling damage, scrap, and safety hazards

- Latest technology to keep machine up and running at its full capacity

- Increased tensile capacity of weld seam by angel shearing design

- Fully automatic machine with PLC control, minimum work cycle time, and easy operation

- Smooth and high-hardness weld seam by automatic TIG weld processing, with no need for grinding

- Communication with uncoiler, flattener and accumulator, realizing one-man operation for the complete entry line section

Technical Data Sheet

| Model No. | Strip Width (mm) | Strip Thickness (mm) | Cycle Time (min) | Welding |

| JH32 | 40 – 120 | 0.6 – 1.6 | ≤ 1.5 | TIG |

| JH50 | 60 – 200 | 1.0 – 3.5 | ≤ 1.5 | TIG/MIG |

| JH76 | 100 – 260 | 1.2 – 3.75 | ≤ 2 | MIG |

| JH89 | 100 – 300 | 1.2 – 4.0 | ≤ 2 | MIG |

| JH114 | 120 – 400 | 2.0 – 5.0 | ≤ 3 | MIG |

| JH165 | 160 – 520 | 2.5 – 7.0 | ≤ 3 | MIG |

| JH219 | 240 – 700 | 3.5 – 8.0 | ≤ 4.5 | MIG |

| JH273 | 320 – 900 | 4.0 – 10.0 | ≤ 5 | MIG |

| JH325 | 300 – 1100 | 5.0 – 12.7 | ≤ 6 | MIG |

| JH406 | 600 – 1300 | 6.0 – 14.0 | ≤ 7 | MIG |

| JH508 | 700 – 1650 | 6.0 – 16.0 | ≤ 8 | MIG |

| JH630 | 900 – 2000 | 6.0 – 22.0 | ≤ 9 | MIG |

| JH660 | 900 – 2200 | 6.0 – 23.0 | ≤ 9 | MIG |

| JH711 | 900 – 2400 | 8.0 – 25.0 | ≤ 10 | MIG |