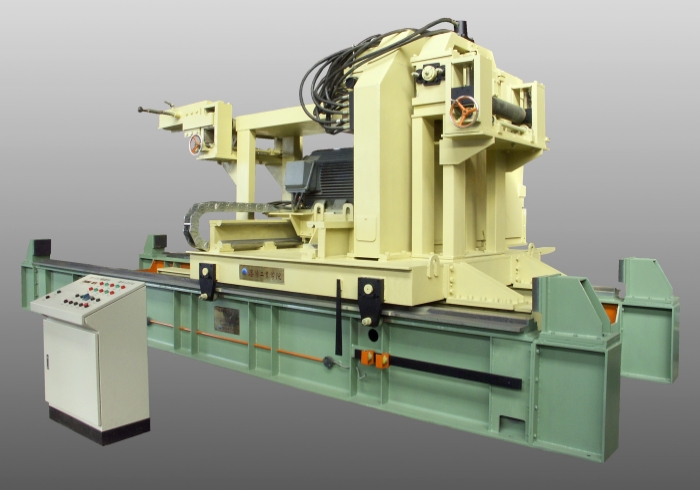

Friction Saw Cut Off

Friction saw Cut Off are the conventional cut off machines for tube and pipe mill with relatively low capital investment required for tube and pipe producer. As the name implies, the friction saw uses heat generated by friction to cut the tube, pipe, or profile coming off the mill.

Friction saw cu off by SRET Equipment enables the cutting of materials to pre-set length in a high precision, with a short cutting cycle. The flying cutting traveling carriage system accelerate to match the tube’s speed, maintain that speed during the cutting process. After the cutting is complete, it then reverse direction in an accelerating mode, till return to its home position, where it waits for next work cycle. The generously dimensioned rack and pinion driving system ensures no vibration during the acceleration motion to quickly reach the correct synchronized speed. The blades are heat-treated to reach a surface hardness, immune to vibrations and resonance phenomena. A fully automatic control system is applied to the machine, with a very user-friendly HMI interface. Once programmed they can operate without requiring the constant presences of operator at the control station.

SRET Equipment has a over 30 years of experiences in manufacturing friction saw cut off, and has been the biggest supplier of it in China’s market.

Value Highlights

- Low cutting time and high production speed achieved.

- Fully automatic controlled by NC with user friendly HMI interface, without constant operator presence at the control station

- AC, DC, or linear servo motor for accelerating of traveling carriage

- High cutting accuracy

- Rugged structure designed for long lasting service life

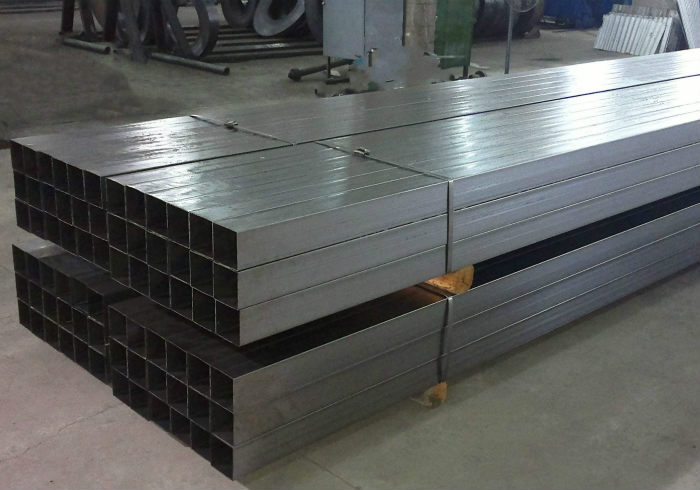

- Able to handle products of various shape: round, square, rectangular, open profile

Technical Data Sheet

| Model No. | Ø (mm) | Thickness (mm) | Length (m) | Tolerance (mm) | Speed (m/min) | Cut Off Mode |

| FJ19 | 10 – 19 | 0.6 – 1.6 | 4 – 12 | ≤ ±2 | 0 – 140 | Pneumatic |

| FJ32 | 10 – 32 | 0.6 – 1.6 | 4 – 12 | ≤ ±2 | 0 – 140 | Pneumatic |

| FJ50 | 20 – 50 | 1.0 – 3.5 | 4 – 12 | ≤ ±3 | 0 – 130 | Pneumatic |

| FJ76 | 32 – 76 | 1.0 – 4.0 | 4 – 12 | ≤ ±3 | 0 – 110 | Pneumatic |

| FJ89 | 38 – 89 | 1.5 – 4.0 | 4 – 12 | ≤ ±3 | 0 – 100 | Pneumatic |

| FJ114 | 50 – 114 | 1.5 – 5.0 | 4 – 12 | ≤ ±3 | 0 – 80 | Pneumatic |

| FJ165 | 89 – 165 | 2.0 – 7.0 | 4 – 12 | ≤ ±3 | 0 – 75 | Pneumatic / Hydraulic |

| FJ219 | 89 – 219 | 2.0 – 8.0 | 6 – 12 | ≤ ±3 | 0 – 75 | Hydraulic |

| FJ273 | 114 – 273 | 4.0 – 10.0 | 6 – 12 | ≤ ±3 | 0 – 50 | Hydraulic |

| FJ325 | 165 – 325 | 5.0 – 12.0 | 6 – 12 | ≤ ±3 | 0 – 45 | Hydraulic |

| FJ406 | 165 – 406 | 4.0 – 14.0 | 6 – 12 | ≤ ±3 | 0 – 40 | Hydraulic |

H Beam

| Model No. | Flange (mm) | Web (mm) | Speed (m/min) |

| FJ300 | 200 x 8 | 300 x 5 | 0 – 50 |

| FJ400 | 250 x 12 | 400 x 8 | 0 – 45 |

| FJ500 | 300 x 12 | 500 x 8 | 0 – 40 |

| FJ600 | 300 x 14 | 600 x 10 | 0 – 35 |

| FJ700 | 400 x 16 | 700 x 12 | 0 – 35 |