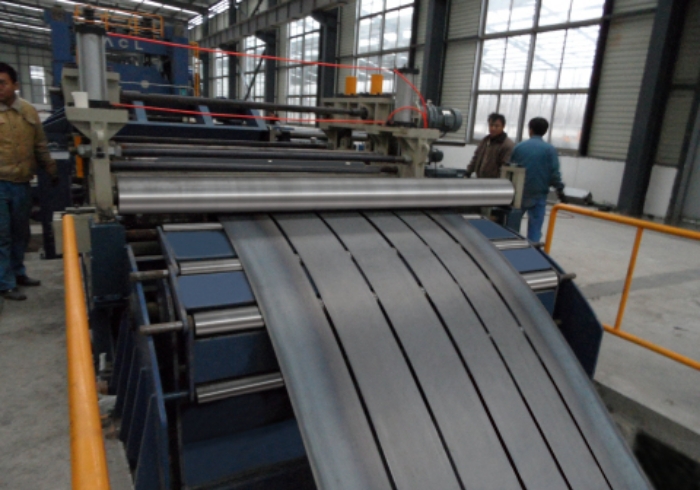

Slitting Line

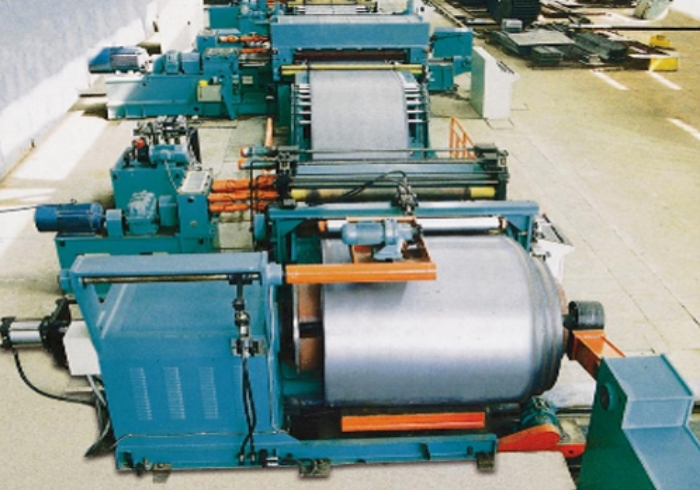

Slitting line is used to cut an entry mother coil of a certain width into several narrower and lighter daughter coils. The general layout of a slitting line provided by SRET Equipment normally includes: coil handling equipment for loading coil, uncoiler, leveler, feeder, edge trimmer, shears, slitter, tensioning machine, and recoiling machine.

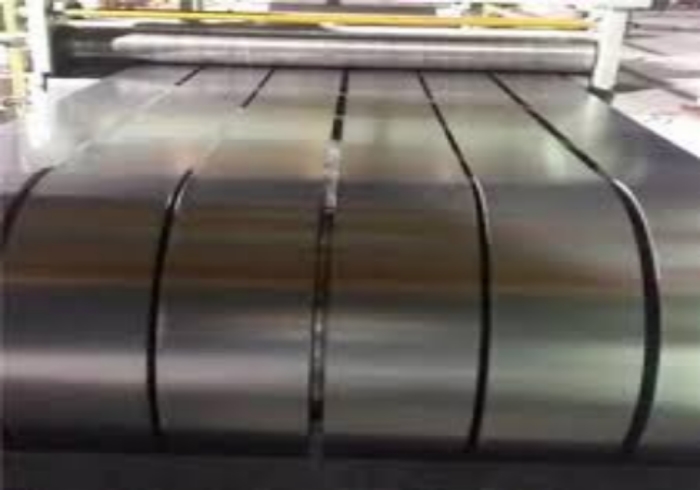

A high quality slitting line requires very stiff and well designed slitter heads with zero axial gaps, absolute parallelism of shafts on rotation, minimum shafts bending, combined with the right tensioning device that is able to provide high tension to the slits without marks on the material surface or edges. With in-depth understanding and experience of this, special attention is paid by SRET Equipment in developing slitting line solutions to help customer tackle these issues in an effective manner.

Running at high speeds and allowing quick tooling setups are two essential ingredients for efficient operation. The target of SRET Equipment is to propose technical solutions specific to customers’ needs and resources, and match the type of products run, the frequency of setup changes, and the labor available to operate the line.

SRET Equipment provide a wide range of slitting lines for various requirements, covering the complete material thickness range from 0.2mm up to 20mm.

Value Highlights

- Operation safety, even for the thickest and hardest strips

- High productivity by minimized down times and changeover times

- High quality of slit edges enabled by high precision slitter heads

- High speed throughput

- Cover a wide range of material thickness

- Automatic brake control

Technical Data Sheet

| Model No. | Coil Thickness (mm) | Coil Width (mm) | Coil Weight (t) | Finished Strip Width (mm) | Slitting Strips Qty | Line Speed (m/min) |

| SL-H-3×2000 | 0.3 – 3.0 | 800 – 2,000 | 20 | ≥25 | ≤30 | Max. 180 |

| SL6x2000 | 1 – 6 | 900 – 2,000 | 30 | ≥50 | ≤10 | Max. 50 |

| SL8x2000 | 2 – 8 | 900 – 2,000 | 30 | ≥70 | ≤8 | Max. 40 |

| SL12x2200 | 3 – 12 | 900 – 2,200 | 35 | ≥80 | ≤7 | Max. 30 |

| SL16x2200 | 4 – 16 | 900 – 2,200 | 35 | ≥100 | ≤5 | Max. 25 |

| SL20x2200 | 5 – 20 | 900 – 2,200 | 35 | ≥150 | ≤3 | Max. 20 |